The Steam Autoclave – The Backbone of Sterile Substrate Production

A high-precision, dedicated steam autoclave is the foundation of contamination-free substrate production, ensuring reliable growing mediums for mushroom cultivation. Manufactured in Japan by world leader in commercial-scale mushroom equipment, this autoclave is trusted by industry pioneers like Eclo (Belgium), Far West Fungi (USA), and BioMycotec (Germany) – renowned facilities known for their large-scale, high-quality production.

Why This Autoclave is Essential

Built for long-term use – Designed for continuous operation, featuring low maintenance requirements and advanced safety controls.

Ensures complete sterilisation – Uses high-pressure steam to eliminate contaminants, bacteria, and competitor fungi in organic materials.

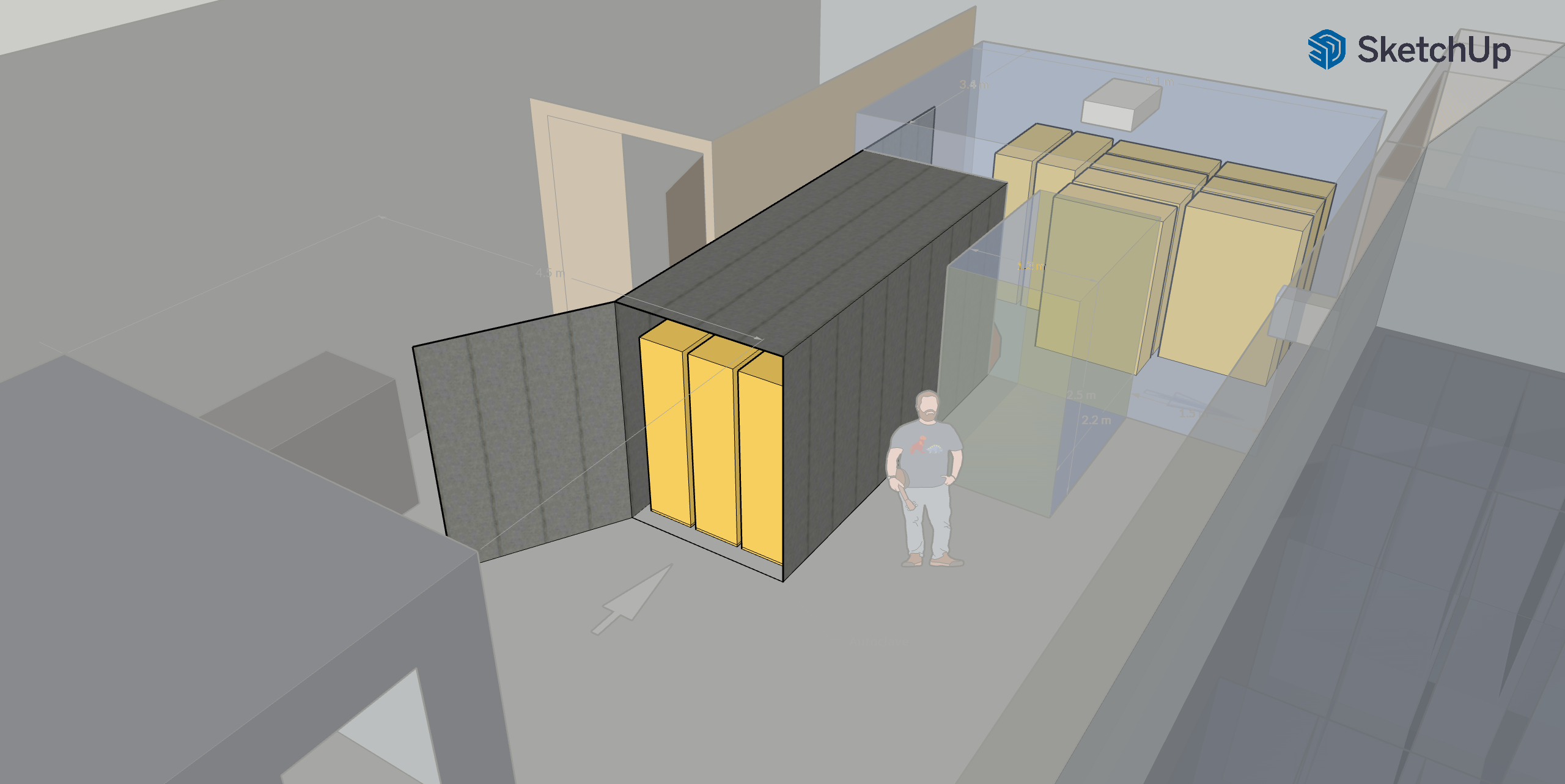

Double-ended pass-through system – Prevents contamination by allowing ‘dirty’ blocks to be loaded from one end while sterilised blocks exit into a cleanroom.

Fully integrated workflow – Once sterilised, blocks cool in a sterile environment before being transferred via a conveyor belt to the inoculation room.

Automated production – An automated spawning machine inoculates and seals the bags before they are moved into a temperature-controlled incubation room for colonisation.

High capacity – Processes 648 x 3kg blocks per cycle, allowing for large-scale production while maintaining strict sterility standards.

The Foundation of Our Facility

This autoclave is the single most important piece of equipment in our production chain. Without it, we cannot produce sterile growing substrates at scale.

- 6-month build time plus delivery – Funding this autoclave is our top priority to ensure timely production.

- Key to scaling our operation – Enables bulk sterilisation services, providing contamination-free materials to both commercial and small-scale growers.

- A long-term investment – Built to last for generations, supporting the UK’s first non-profit commercial mushroom production hub.

What Does a Steam Autoclave Do?

A steam autoclave is an industrial sterilisation chamber that uses high-pressure steam to kill contaminants, bacteria, and competitor fungi in organic materials. In commercial mushroom production, it is essential for producing reliable, contamination-free growing substrates.

Its Role in Our Facility

- Sterilises bulk substrate and grain spawn to create a perfect growing environment for mushrooms.

- Prevents contamination, which is the biggest risk in large-scale mycology.

- Ensures product consistency, allowing us to supply high-quality, sterile materials to commercial and small-scale growers.

- Enables bulk sterilisation services, giving growers access to high-quality sterilised substrates without expensive in-house equipment.

Additional Info

Payment Terms: 50% upfront, 50% upon loading

Lead time / Production Time: 6 months

Shipping Time: Sea Cargo, 50 days.

Why This Autoclave is Essential

- Built to Last: Engineered for continuous, repeated sterilisation cycles, designed to last for generations with minimal maintenance.

- High Capacity: Can process 648 x 3kg blocks of substrate per cycle, significantly scaling up our production output.

- Safety & Efficiency: Comes equipped with advanced safety controls and low maintenance requirements, making it a cost-effective and reliable solution for long-term operations.

- Custom-Built: Each unit is made to order, ensuring it meets the specific needs of our facility.

Why We Need to Fund This First

The steam autoclave is the single most important piece of equipment in our production chain. Without it, we cannot produce sterile growing substrates at scale. With a 6-month build time, securing funding early is critical to avoid delays.

By investing in this autoclave, we ensure the foundation of our entire operation is secure, allowing us to rapidly scale and provide high-quality, contamination-free mushroom cultivation materials to growers across the UK.