Modular Cleanrooms – Ensuring Sterility for Automated Block Inoculation

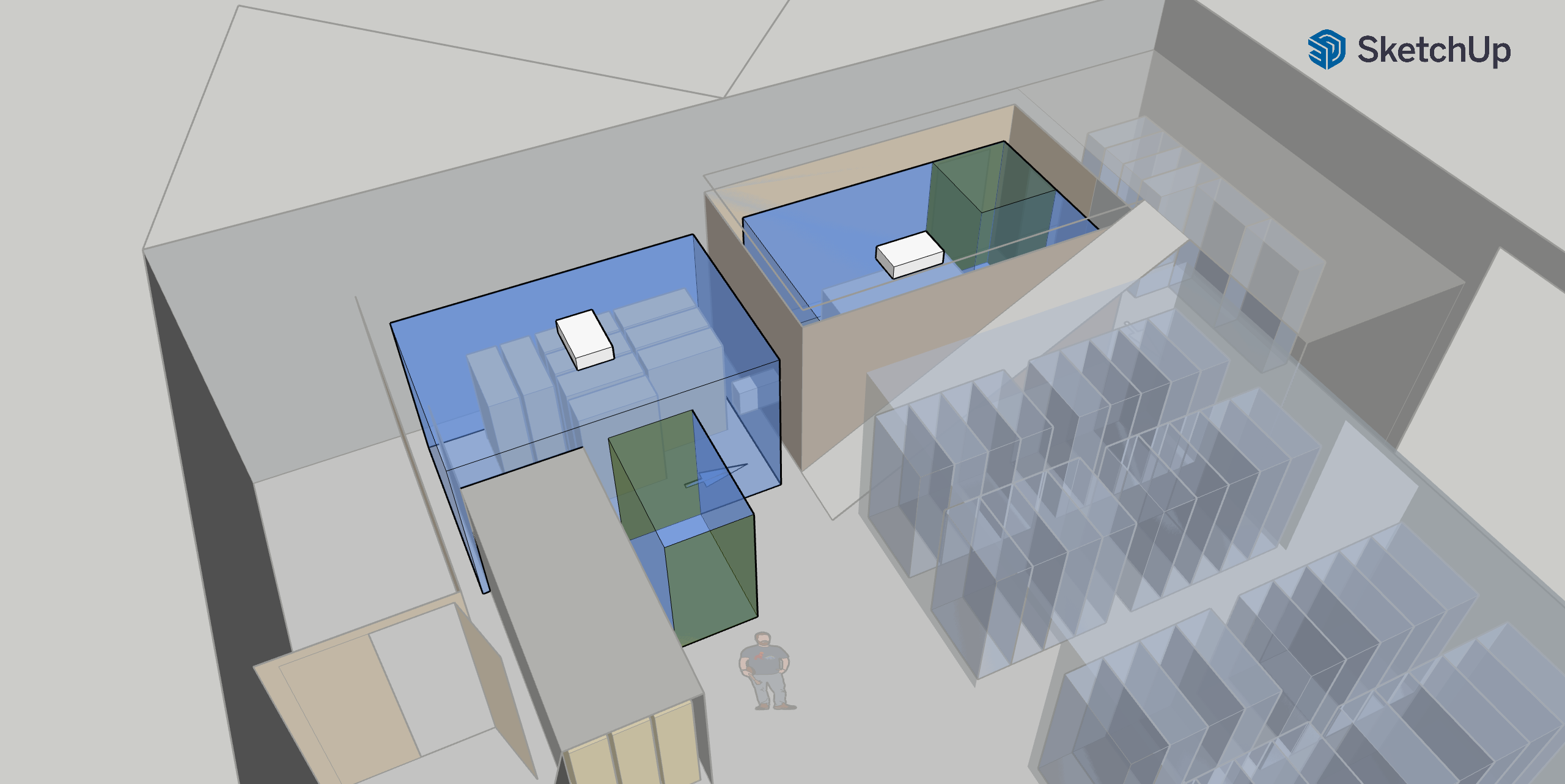

To maintain the highest standards of sterility and efficiency, we require two dedicated modular cleanrooms equipped with HEPA-filtered air systems. These controlled environments are essential for cooling sterilised substrate blocks and automating the inoculation process, ensuring contamination-free production at scale.

We have been in deep discussions with multiple cleanroom suppliers to finalise the perfect solution tailored to our facility’s needs. These cleanrooms will be designed to seamlessly integrate into our workflow, ensuring maximum sterility and efficiency.

One cleanroom will be used exclusively for cooling blocks after autoclave sterilisation, preventing airborne contamination before inoculation. The second cleanroom will house an automated block inoculation machine, which will open, inoculate, and seal the blocks, removing human handling, reducing labour, and eliminating contamination risks.

Why These Modular Cleanrooms are Essential

Ensures Complete Sterility – HEPA-filtered air systems provide a controlled environment, preventing contamination during cooling and inoculation.

ISO-Compliant Cleanroom Standards – The block cooling room will be built to ISO specifications to maintain industry-leading cleanliness.

Automated Inoculation for Precision & Efficiency – The adjoining cleanroom will house an automated spawning machine, eliminating manual handling and contamination risks.

A Leap Beyond Small-Scale Production – Small-scale producers must inoculate blocks manually using laminar flow hoods, which is labour-intensive and introduces contamination risks. Our fully automated, sterile system removes these risks entirely.

The Role of These Cleanrooms in Our Facility

Fully Integrated with Our Workflow: The autoclave, conveyor system, and incubation rooms will work in tandem to ensure a smooth, contamination-free process from sterilisation to incubation.

Block Cooling Room: Ensures that substrate blocks cool in a sterile environment before inoculation, preventing contamination risks.

Inoculation Cleanroom: Hosts the automated spawning machine, which will open, inoculate, and seal the blocks before transfer to the temperature-controlled incubation spaces.

Additional Info

Includes installation, HEPA filtration systems, and full compliance with ISO cleanroom standards.

Why We Need Funding for This Equipment

These modular cleanrooms are critical to achieving a fully automated, contamination-free workflow. Without them, we would be forced to rely on labour-intensive manual inoculation processes, increasing contamination risks and reducing production efficiency.

With discussions underway with multiple suppliers, securing funding now will allow us to finalise our cleanroom solution, place orders, and implement a fully integrated, sterile production process as soon as possible.